Basements are constructed below ground level and are therefore subject to ground water pressure. If insufficient external drainage or a failure in waterproofing, water ingress will result. The following information is designed for practical advice in three situations:

NEW CONSTRUCTION

In Australia, there is no specific standard for below-ground waterproofing. Instead, we rely on designing a Performance Solution to meet the required Performance Requirements. A Performance Solution must comply with the National Construction Code (NCC) and often incorporates site-specific strategies based on the “Deemed-to-Satisfy” principles outlined in AS4654.2.

A useful reference for below-ground waterproofing is British Standard 8102, which classifies construction designs into three grades of watertightness:

- Grade 1: Some seepage and damp patches are acceptable.

- Grade 2: No water penetration is allowed, but some moisture vapor is tolerable.

- Grade 3: A completely dry environment is required.

Regardless of the required grade of watertightness, it is always advisable to implement multiple layers of defense. Engaging a waterproofing expert during the design phase offers significant benefits, including expert judgment, strategic advice, and formal documentation of basement waterproofing Performance Solutions.

For expert consultation, contact David Hepworth at 0412 106 450 or email at david@conpro.com.au

AIW – Honorary Life Member

AIW – Honorary Life Member

Most residential projects have a relatively kind environmental impact and the strategy will involve drainage, structural integrity and positive waterproofing. Simple strategies are outlined Sika BELOW GROUND- Performance Solution Strategies . Performance Solutions often refer to pre-established D-t-S references, a good example is the External Waterproofing Standard AS4654.2, reference 2.13 Planter Boxes for principles of barrier protection and drainage. (TECHNICAL TIPS – Waterproofing Planter Boxes). Many commercial constructions have far more demanding criteria and strategies need to well thought through in the design phase. NB: A final tip in basement construction is to allow sufficient ventilation to avoid condensation issues.

Key Products:

- swell-a-2010-m

- swell-s-2-505

- kuniseal-c-31-ds-2-page

- Contec C1 – Crystalline Growth Compound

- FLEX-PRO – version 2018 (3)

- Sikalastic-1K-pds

- Polycloth – reinforcing fabric

- Sikalastic-777 -Root resistant Polyurethane

- FLEXIPRO – Below Ground Waterproofing Membrane

- Protection Board

- Drainage Cell Brochure

- Geosheet – drainage cell with geofabric

- Megaflo – Geocomposite Panel Drain System

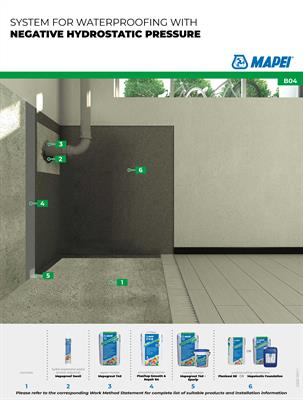

- Mapei – Waterproofing Structures Installed Below Ground Level

- Mapei – Technical Design for Waterproofing Below Ground

Reference Information:

Sika BELOW GROUND- Performance Solution Strategies

youtube: Bond Breaker system

Principles of Below Ground Waterproofing – BS 8102

REMEDIAL BASEMENT WORKS

Basement Waterproofing Challenges & Remedial Solutions in Australia

In Australia, basement waterproofing issues are widespread due to several factors, including:

- Poor design and construction practices

- Lack of clear industry guidelines

- No specific waterproofing standards under the National Construction Code (NCC)

- Differing expectations between owners and builders regarding performance

Common Waterproofing Strategies & Their Limitations

During construction, commercial and residential buildings typically rely on two primary waterproofing strategies:

- Positive tanking membrane systems

- Drainage solutions

Over time, if these systems fail, basement water issues become a major concern.

Remedial Solutions & Multi-Defense Strategies

Effective remedial work for basement ceilings, walls, slabs, and pits requires a multi-layered defense approach, integrating:

- Positive and negative waterproofing treatments

- Enhanced drainage systems

- Improved ventilation

Warranty & Regulatory Considerations

Most basement remedial works do not come with a warranty or guarantee. This is because:

- The condition of the original building substrate is often unknown.

- The scope of remedial work typically does not require a Building Permit.

- These works are usually classified as maintenance and repairs under the Victorian Building Regulations 2018, Schedule 3, Clause 3—not subject to NCC requirements.

Finding the Right Solution

Every basement waterproofing issue is unique. Some solutions can fully resolve the problem, while others focus on managing ongoing moisture issues. We offer expert guidance on practical applications and product options tailored to your specific situation.

A site visit consultation is often the best starting point—see our “Services” section for more details.

Contact us to discuss the best approach for your basement waterproofing needs.

email david@conpro.com.au or Mob: 0412106450.

REPAIR WALLS

Existing walls which have moisture or water penetrating internally, require treatment from the ‘negative side’. The two most common strategies is to either treat the brick, block, mortar with a crystalline growth treatment to stop the water, or to form a new barrier on the surface. Both methods are valid, but results will vary by situation.

Key Products:

- Contec PLUG – Rapid Set Compound

- Contec C1 – Crystalline Growth Compound

- sikalastic-1k-pds

- Dimacoat – Water Based Two Part Epoxy Coating

- Sikalastic WPU-en-AU-07-2021-1-1

- Injection CYH 500 Hydrophobic PU

- FIX HH _AU_ – 807

Reference Information:

Waterproofing Basements.pdf

FLOOR JOINT REPAIR

The most common failure occurs in the floor/wall joint. Depending on circumstances, the water needs to be managed or stopped by repair. To repair from the ‘negative side’ usually requires mechanical assistance to penetrate the surface. If it is a rising damp issue, form a line barrier through damp coursing. Mortar or cracks can be repaired with crystalline growth treatment. Whilst weaknesses in the slab or wall can be retarded via forming a new barrier on the surface.

Key Products:

- d-barrier-damp-coursing-application-guide Damp Course Liquid

- Contec PLUG – Rapid Set Compound

- Contec C1 – Crystalline Growth Compound

- sikalastic-1k-pds

- Dimacoat – Water Based Two Part Epoxy Coating

- Injection CYH 500 Hydrophobic PU